Integral Screw Stabilizer – Precision Wellbore Control and Vibration Reduction Tool

Product Technical Introduction

The Integral Screw Stabilizer is a high-performance downhole drilling tool designed to enhance wellbore stability, directional control, and drilling efficiency. Unlike traditional multi-piece stabilizers, the integral screw design integrates the blade and body into a single machined piece, offering superior mechanical strength, alignment, and durability.

This stabilizer is particularly suited for directional and horizontal drilling, extended-reach wells, and formations prone to vibration or washout.

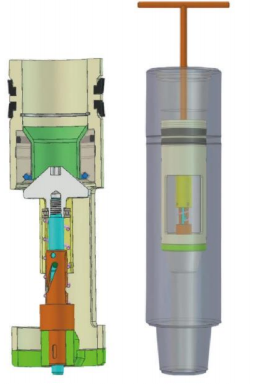

Working Principle & Mechanical Design

The integral stabilizer uses precision-machined blades arranged around a solid body. These blades contact the wellbore, helping maintain the drill string in the desired trajectory while minimizing lateral vibration.

Key features include:

- Fully integral, one-piece construction for maximum strength

- Precision-engineered screw threads or grooves for optimized stabilizer-housing connection

- Even distribution of radial forces to reduce stress concentration

- Smooth hydraulic flow around blades to minimize turbulence

By maintaining consistent contact with the borehole wall, the integral screw stabilizer improves hole quality, gauge retention, and directional accuracy.

Operational Benefits

Using an integral screw stabilizer provides multiple operational advantages:

- Enhanced wellbore stabilization in directional or deviated wells

- Reduced lateral vibration and stick-slip phenomena

- Increased durability under high torque and bending loads

- Improved bit-to-borehole alignment and drilling efficiency

- Compatible with a wide range of BHA configurations

This tool is designed for long-term reliability in challenging formations while reducing non-productive time (NPT) caused by wellbore instability.

Design, Materials & Reliability

- High-strength alloy steel for body and blade construction

- Precision machining for uniform blade height and consistent geometry

- Hardfacing or wear-resistant surface treatment on blades for extended service life

- Integrated threaded connections to prevent mechanical loosening under torque

This robust design ensures consistent performance under high-pressure, high-torque, and abrasive conditions.

Typical Applications

- Directional and horizontal drilling

- Extended-reach drilling (ERD)

- Wells with unstable or soft formations

- Wellbore vibration mitigation

- Hole gauge retention and trajectory control