Kelly Cock – Reliable Well Control Valve for Drilling Safety

Product Technical Introduction

The Kelly Cock is a critical well control valve installed in the drill string to prevent uncontrolled backflow of drilling fluid, gas, or formation pressure during drilling operations. It serves as a primary safety barrier between the wellbore and the rig floor.

Kelly cocks are typically installed at the top and/or bottom of the kelly, allowing rapid shut-in of the drill string in the event of a kick, backflow, or unexpected pressure surge.

Functional Role in Drilling Operations

During normal drilling, the Kelly Cock remains fully open to allow unrestricted circulation of drilling fluid. In abnormal conditions, it can be quickly closed manually to isolate wellbore pressure and prevent fluid or gas from escaping through the drill string.

Its main functions include:

- Preventing backflow from the wellbore

- Providing immediate pressure isolation

- Protecting personnel and surface equipment

- Supporting overall well control procedures

The valve plays a vital role in maintaining operational safety and pressure integrity.

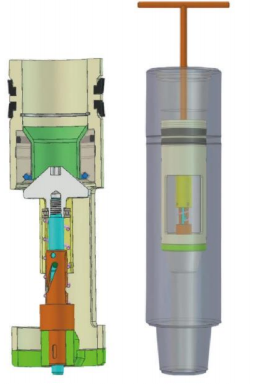

Structural Design & Sealing Performance

Kelly Cocks are designed as full-opening ball valves, ensuring minimal pressure loss and smooth fluid passage when open. Key design features include:

- Full-bore internal flow path

- High-pressure metal-to-metal or elastomer-assisted sealing

- Positive shut-off under high pressure

- Low operating torque for fast manual operation

The robust valve structure ensures reliable sealing even under high-pressure, high-flow drilling conditions.

Materials & Mechanical Strength

Manufactured from high-strength alloy steel, Kelly Cocks are heat-treated to withstand:

- High internal pressure

- Torsional loads from drill string rotation

- Abrasive drilling fluids

- Corrosive downhole environments

Precision machining and strict quality control ensure long service life and consistent sealing performance.

Installation Types & Configuration

Kelly Cocks are commonly supplied as:

- Upper Kelly Cock

- Lower Kelly Cock

- Manual or wrench-operated versions

They are manufactured in compliance with API specifications, with standard connections compatible with common kelly and drill string thread types.

Operational Advantages

- Immediate well control response

- Reliable pressure isolation

- Full-bore flow with minimal pressure loss

- Simple structure and easy operation

- Essential safety component for drilling rigs