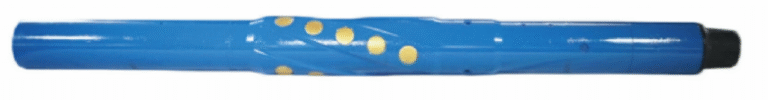

Oil Drilling Flap Valve – One-Way Flow Control and Backflow Prevention

Product Technical Introduction

The Oil Drilling Flap Valve is a one-way flow control device designed to prevent reverse flow of drilling fluid, gas, or formation pressure during drilling and workover operations. It plays a critical role in maintaining wellbore pressure control and protecting surface equipment and personnel.

By allowing fluid to flow in one direction only, the flap valve helps prevent backflow through the drill string or circulation system, especially during pump shutdowns or abnormal pressure conditions.

Working Principle & Flow Control Mechanism

The flap valve operates using a hinged or spring-assisted flap mechanism. During normal circulation, forward fluid flow opens the flap, allowing unrestricted passage of drilling fluid. When flow stops or reverses, the flap automatically closes under gravity, spring force, or pressure differential.

Key functional characteristics include:

- Automatic one-way flow control

- Fast response to reverse pressure

- No external actuation required

- Reliable sealing under variable flow conditions

This simple and dependable mechanism ensures rapid backflow prevention in critical drilling operations.

Structural Design & Sealing Performance

The valve is designed with a compact, robust internal structure, ensuring stable operation under high flow rates and pressure fluctuations. Sealing surfaces are engineered to provide effective shutoff while minimizing wear caused by abrasive drilling fluids.

Design features include:

- Full-flow internal passage

- Low pressure drop during forward flow

- Durable flap and hinge structure

- Wear-resistant sealing surfaces

Materials & Mechanical Strength

Manufactured from high-strength alloy steel, the oil drilling flap valve is heat-treated to withstand:

- High internal pressure

- Abrasive and high-solids drilling fluids

- Repeated opening and closing cycles

- Harsh oilfield environments

Optional corrosion-resistant materials are available for sour service or special applications.

Operational Advantages

- Automatic backflow prevention

- Simple structure with high reliability

- No manual operation required

- Low maintenance and long service life

- Enhanced well control safety

Typical Applications

- Drilling circulation systems

- Drill string flow control

- Workover and well servicing operations

- Backflow prevention during pump shutdowns

- Pressure control in drilling operations