Kelly Cock multifuncional: control de caudal y seguridad integrados para operaciones de perforación

Introducción técnica del producto

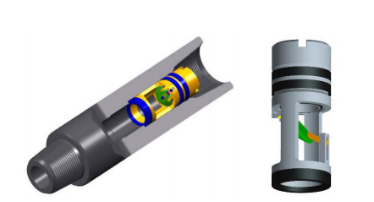

En Polla Kelly Multifuncional is a critical drilling safety valve installed in the Kelly drilling system, designed to control, isolate, and shut off drilling fluid flow under normal and emergency operating conditions. By integrating multiple operational functions into a single valve body, this tool enhances rig safety, simplifies operation, and improves overall drilling efficiency.

Compared with conventional single-function Kelly cocks, the multi-functional design provides greater flexibility and reliability in complex drilling environments.

Functional Capabilities & Operational Role

The multi-functional Kelly cock is designed to perform several key functions during drilling operations, including:

- Rapid shut-off of drilling fluid flow

- Isolation of internal pressure in the drill string

- Prevention of uncontrolled fluid discharge

- Support for emergency well control procedures

Installed at the upper or lower section of the Kelly, the valve allows operators to quickly respond to abnormal pressure situations while maintaining control over drilling fluid circulation.

Working Principle & Control Mechanism

The valve operates through a robust internal sealing and flow-blocking mechanism, activated either manually or via mechanical actuation depending on configuration. When closed, the valve provides reliable isolation, preventing drilling fluid from flowing through the Kelly and drill string.

Precision-machined internal components ensure:

- Smooth opening and closing

- Reliable sealing under high pressure

- Minimal pressure loss during normal circulation

- Long-term operational stability

Diseño, materiales y fiabilidad

The multi-functional Kelly cock is manufactured from acero de aleación de alta resistencia, offering excellent resistance to pressure, torque, and fatigue. Advanced sealing materials ensure dependable performance under high-pressure, high-flow drilling conditions.

The compact and integrated structure reduces the number of separate components in the drilling assembly, lowering maintenance requirements and improving reliability.

Ventajas operativas

- Multiple safety and control functions in one valve

- Fast response during pressure anomalies

- Improved rig floor safety

- Reduced equipment complexity

- Suitable for demanding drilling environments

Aplicaciones típicas

- Operaciones de perforación de petróleo y gas

- Sistemas de perforación Kelly

- Well control and emergency isolation

- Circulación de fluidos de perforación a alta presión

- Rig floor safety enhancement