Alloy Rotary Friction & Torsion Reducing Joint – Advanced Casing Protection and Wear Reduction Solution

Product Technical Introduction

The Alloy Rotary Friction Reducing and Torsion Reducing Joint, also known as the Alloy Rotary Casing Anti-Wear Joint, is a specialized downhole tool designed to minimize friction, reduce torsional stress, and protect casing strings during drilling and casing running operations.

By integrating a high-strength alloy body with a rotary anti-wear structure, this joint significantly reduces contact friction between the casing and wellbore, improving operational efficiency and extending casing service life—especially in deviated, horizontal, and extended-reach wells.

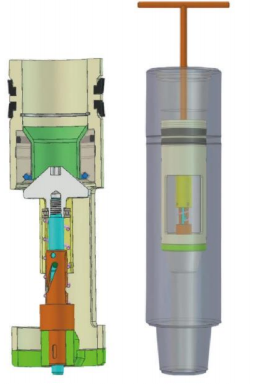

Working Principle & Friction Reduction Mechanism

During drilling or casing running, casing strings are subjected to continuous rotation, axial load, and lateral contact with the wellbore. The alloy rotary friction reducing joint introduces a rotational interface that allows relative motion between the casing and the wellbore contact surface.

Key functional mechanisms include:

- Rolling or rotary movement to replace sliding friction

- Reduced torque transmission to the casing string

- Lower axial drag during running and rotation

- Minimized casing wear and deformation

This design effectively converts high-friction sliding contact into low-friction rotational contact, significantly reducing mechanical stress.

Torsion Reduction & Mechanical Protection

In addition to friction reduction, the joint helps absorb and redistribute torsional loads, preventing excessive torque accumulation along the casing string. This is particularly critical in complex well profiles where high torque and drag can lead to casing damage or running difficulties.

Benefits include:

- Reduced torsional stress on casing

- Improved casing running safety

- Lower risk of casing deformation or failure

- Enhanced control during rotation and reciprocation

Design, Materials & Durability

The joint is manufactured from high-strength alloy steel, offering excellent resistance to:

- Abrasion and casing wear

- High torque and axial load

- Fatigue under cyclic rotation

- Harsh downhole environments

Wear-resistant alloy surfaces and precision machining ensure long service life and stable performance under demanding drilling conditions.

Operational Advantages

- Significant reduction of friction and torque

- Enhanced casing wear protection

- Improved casing running efficiency

- Suitable for high-angle and horizontal wells

- Increased operational reliability and safety

Typical Applications

- Casing running operations

- Deviated and horizontal wells

- Extended-reach drilling (ERD)

- High-torque and high-drag well conditions

- Casing wear protection systems