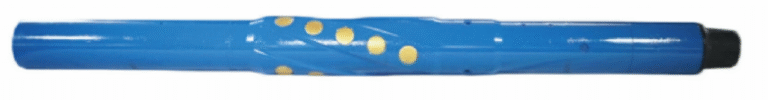

Self-Priming Float Valve – Reliable Backflow Prevention for Drilling Operations

Product Technical Introduction

The Self-Priming Float Valve is a downhole one-way flow control device designed to prevent backflow of drilling fluid while enabling rapid priming and stable circulation during oil and gas drilling operations. Installed in the drill string or bottom hole assembly (BHA), it plays a key role in maintaining pressure control and protecting surface and downhole equipment.

Unlike conventional float valves, the self-priming design allows the valve to open smoothly during initial circulation, reducing priming time and minimizing pressure fluctuation.

Working Principle & Self-Priming Mechanism

The self-priming float valve operates automatically based on pressure differential. During normal circulation, drilling fluid pressure overcomes the spring or gravity-assisted sealing mechanism, allowing fluid to flow downward through the valve.

When circulation stops or reverse pressure occurs, the valve closes instantly to prevent backflow. The self-priming feature ensures:

- Faster pressure buildup during pump start-up

- Smooth opening without pressure shock

- Stable flow during circulation initiation

- Reliable sealing during shutdown

This design improves operational efficiency while maintaining effective backflow protection.

Operational Functions & Benefits

The self-priming float valve provides several key advantages:

- Prevents reverse flow of drilling fluid

- Reduces pump start-up time

- Minimizes pressure surges and hydraulic shock

- Protects pumps, drill string, and downhole tools

- Enhances circulation stability and safety

Its automatic operation eliminates the need for manual control, ensuring consistent performance in demanding drilling environments.

Design, Materials & Reliability

Manufactured from high-strength alloy steel, the valve body offers excellent resistance to pressure, erosion, and fatigue. Precision-machined internal components and durable sealing elements ensure long service life under high-pressure, high-flow drilling conditions.

The compact structure allows easy integration into standard drill string assemblies without affecting overall hydraulic performance.

Standards & Compatibility

Thread connections and pressure ratings are designed to meet relevant API specifications, ensuring compatibility with standard oilfield drilling equipment and fluid circulation systems.

Typical Applications

- Drilling fluid circulation systems

- Drill string backflow prevention

- Pump protection

- Directional and horizontal drilling

- Workover and well servicing operations